Your current location: Home > Technical Support > Popular Science Column > Fermion 100 Que...

Your current location: Home > Technical Support > Popular Science Column > Fermion 100 Que... 26. What are the differences between the various heating methods for the sample stage (infrared, resistance heating wire)?

The above question is a bit vague, because the resistance wire heating sample stage and infrared heating have a certain overlap. To explain this problem clearly, we must first classify the heating methods. According to the form of heat conduction, there are three main ways to transfer different heat:

● Contact heat transfer

● Radiation heat transfer

● Convection

Among them, convection is rare inside a vacuum, but it is not non-existent. For example, the convection performance of rarefied helium can be used for shock absorption and heat conduction; the main heat transfer inside a vacuum depends on thermal contact and radiation heat transfer.

The so-called thermal contact is relatively easy to understand. It is generally used in low-temperature areas. The main medium is high thermal conductivity metals such as copper and aluminum. It relies on a good contact surface to improve the efficiency of heat conduction. It is often necessary to use a flexible medium (such as In) on the contact surface and increase pressure on the contact surface to improve thermal conductivity.

Radiative heat transfer is much more complicated. The radiation can be in the form of infrared, laser, or even electron beam or ion beam. We often say that resistance heating is to use infrared radiation to heat the sample with infrared radiation from the heating wire, but this method has limitations, because as the sample reaches a high temperature, the sample itself also emits infrared rays, especially as the sample temperature rises, the absorption and emission of infrared radiation will tend to balance, and it is difficult to use infrared radiation to reach a higher temperature at this time, so we generally do not exceed 1000℃ for the temperature range of resistance heating, and the conventional index is generally 800℃.

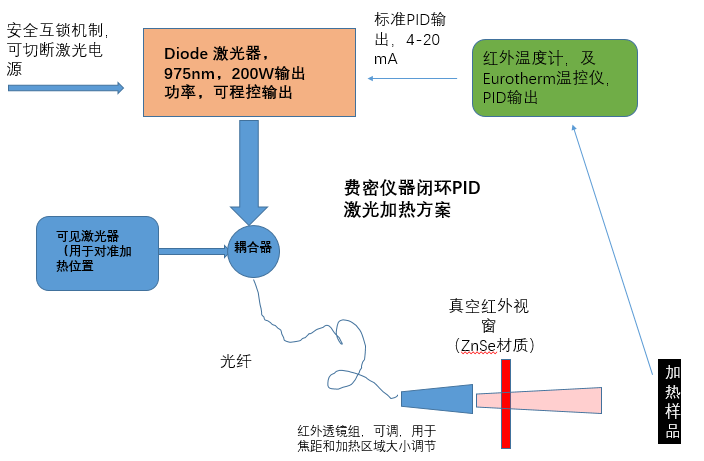

In order to achieve higher temperatures, there are two common methods. One is to use an infrared radiation source with higher energy density. The more common one is to use infrared lasers. Because of the collimation and high energy density of lasers, hundreds of watts of energy can be focused on a millimeter-level point, so the heating efficiency will be much better than conventional resistance heating, and even a small sample can be heated from room temperature to 1000℃ within 10s.

Because of the cost of lasers and the safety temperature of high-power lasers, another common method in actual experiments is electron beam heating, which is only one step away from conventional resistance heating. Generally speaking, if the high voltage is removed from electron beam heating, it is just a conventional resistance heating module. If we add high voltage to the filament or sample, we can upgrade the resistance heating to electron beam heating. At this time, the thermally emitted electrons on the filament will be directed to the sample in a direction, thereby achieving concentrated and high-density energy transfer.

27. How does the laser heater work? And how do companies calculate the output power of laser heaters?

Conventional vacuum heating methods include resistance thermal radiation heating or electron beam bombardment heating, which are highly dependent on vacuum.

Conventional tungsten and tantalum heating wires can only guarantee a relatively long life in ultra-high vacuum, while the alternative precious metal alloy wires, such as platinum-rhodium wires, have requirements for the atmosphere, otherwise they will participate in the reaction or interfere with the experimental process; in addition, the heating efficiency of conventional thermal radiation or electron beam bombardment will drop significantly when the vacuum becomes worse. The main reason is that denser gas molecules absorb infrared radiation and electron beams, causing the power at the actual sample to drop rapidly.

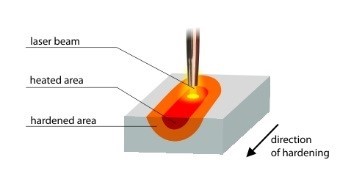

In order to meet the user's heating needs under near-normal pressure and special atmosphere, laser heating has been developed and widely used in different experimental fields. Laser heaters use photons to excite electrons in the material as a heat transfer carrier, or generate Joule Heating through electric current. "Hot processing" uses a laser beam with a high energy density (it is a concentrated energy flow) to irradiate the surface of the processed material. The surface of the material absorbs the laser energy and produces a thermal excitation process in the irradiated area, thereby causing the temperature of the material surface (or coating) to rise, resulting in deformation, melting, ablation, evaporation, etc.

Compared with traditional electric heating methods, laser heating does not need to consider the internal circuit loss and thermal insulation problems of the vacuum, and does not need to consider the design of the shielding layer, so the equipment design is simpler. The power is concentrated, the heat loss is small, and the maximum output power of a laser with a rated power of 200W can reach more than 300W. It can be concentrated in a small area and can quickly heat the sample to more than 1000℃.

The current laser working voltage is 12V, and the output power = 12V × set current.

28. How does the He mass spectrometer in the leak detector work? What is the difference with the commonly used SRS mass spectrometer?

The working principle of the SRS mass spectrometer is quadrupole mass spectrometry. The AC and DC bias voltages applied to the quadrupoles can be used to select charged particles with different nucleus-mass ratios. Its structure is more complex and suitable for mass spectrometry scanning analysis over a wide range.

The quadrupole in the leak detector has a simpler structure because the test object has been determined to be He. Basically, the sensitive area is around 4. In actual operation, it only needs to be slightly adjusted to ensure that the most sensitive test area is for He.