Application of plasma in sterilization and disinfection

Time: 2020.04.03Source: View: 3670

Sterilization and disinfection play an important role in public health. The new coronavirus epidemic has posed a great challenge to traditional sterilization and disinfection technologies, exposing the current lack of sterilization and disinfection devices that can quickly, thoroughly and batch-process masks, protective clothing, etc. Traditional sterilization and disinfection methods have limitationsCurrently, the medical industry mainly relies on high temperature or chemical methods for sterilization and disinfection, which have different defects or limitations. Since many materials in medical machinery are heat-sensitive, high-temperature applications are greatly restricted; chemical agents such as alcohol, etc., are not suitable for wet-sensitive materials when soaked or wiped, and have weak penetration and are prone to incomplete disinfection; although low-temperature fumigation has overcome the above defects, the sterilization time is long and residues need to be handled (such as ethylene oxide decomposition treatment for up to 14 days, which seriously limited the production capacity conversion of masks in the early stage of the epidemic). Some emerging disinfection methods, such as radiation sterilization, can be carried out at room temperature, sterilize quickly, as short as tens of minutes or even minutes, and leave no residue. However, radiation propagates in a straight line, and the sterilization effect is greatly reduced if the rays cannot reach it. Objects with complex structures or shielding cannot be sterilized in all directions.Plasma sterilization is pollution-free, residue-free, and more efficientPlasma is the fourth state of matter in the universe besides gas, liquid, and solid. When the energy is high enough, the outer electrons break free from the constraints of the nucleus and "ionize" to become free electrons, forming a gas-like substance composed of electrons, ions, neutral atoms or groups and still maintaining electrical neutrality, which is plasma. It can be divided into high-temperature plasma and low-temperature plasma. The mass of different particles varies greatly. Although the temperature of electrons is very high during the discharge process, the temperature of heavy particles is very low, and the entire system is in a low-temperature state, so it is called low-temperature plasma, which has a bactericidal and disinfecting effect, and has many advantages such as normal temperature disinfection, no residue and no side effects. At present, the most widely used is the hydrogen peroxide "plasma sterilizer", but many studies have shown that the hydrogen peroxide plasma ionization process only removes residual hydrogen peroxide, and is not a true plasma sterilization and disinfection, and can only be considered as a plasma-assisted sterilization and disinfection method. In addition, there are very few devices for low-temperature plasma sterilization and disinfection, because traditional plasma technology is difficult to manufacture large-volume sterilization and disinfection equipment. The reason for this is that we have to start with the plasma generation mechanism. High-voltage discharge is a common way to obtain plasma, but directly ionizing gas between two metal electrodes is prone to form sparks or arc discharges with high temperatures, which is not conducive to application in the biomedical field. In order to obtain low-temperature plasma that can be used in biomedicine, dielectric barrier discharge (DBD), surface discharge, plasma jet and other methods are usually used. Among them, dielectric barrier discharge and surface discharge are to add an insulating layer between the electrodes to prevent electrode breakdown, but the working distance between the two electrodes is very small, so it is difficult to make large-volume sterilization and disinfection equipment; the plasma ejected by the plasma jet is very limited, and it is also difficult to apply to large-volume sterilization and disinfection equipment. Fermion Instruments' low-temperature plasma sterilization and purification equipment has significant effectsTo meet the growing demand for sterilization and disinfection equipment in public health, especially in the current COVID-19 epidemic where time is life, masks, protective clothing, etc. need to be sterilized and disinfected quickly, thoroughly, and in batches, Fermion Instruments has broken through the electrode structure and size limitations of traditional plasma discharge, and used a new remote low-temperature plasma technology to develop a new large-volume vacuum low-temperature plasma sterilization and purification equipment.

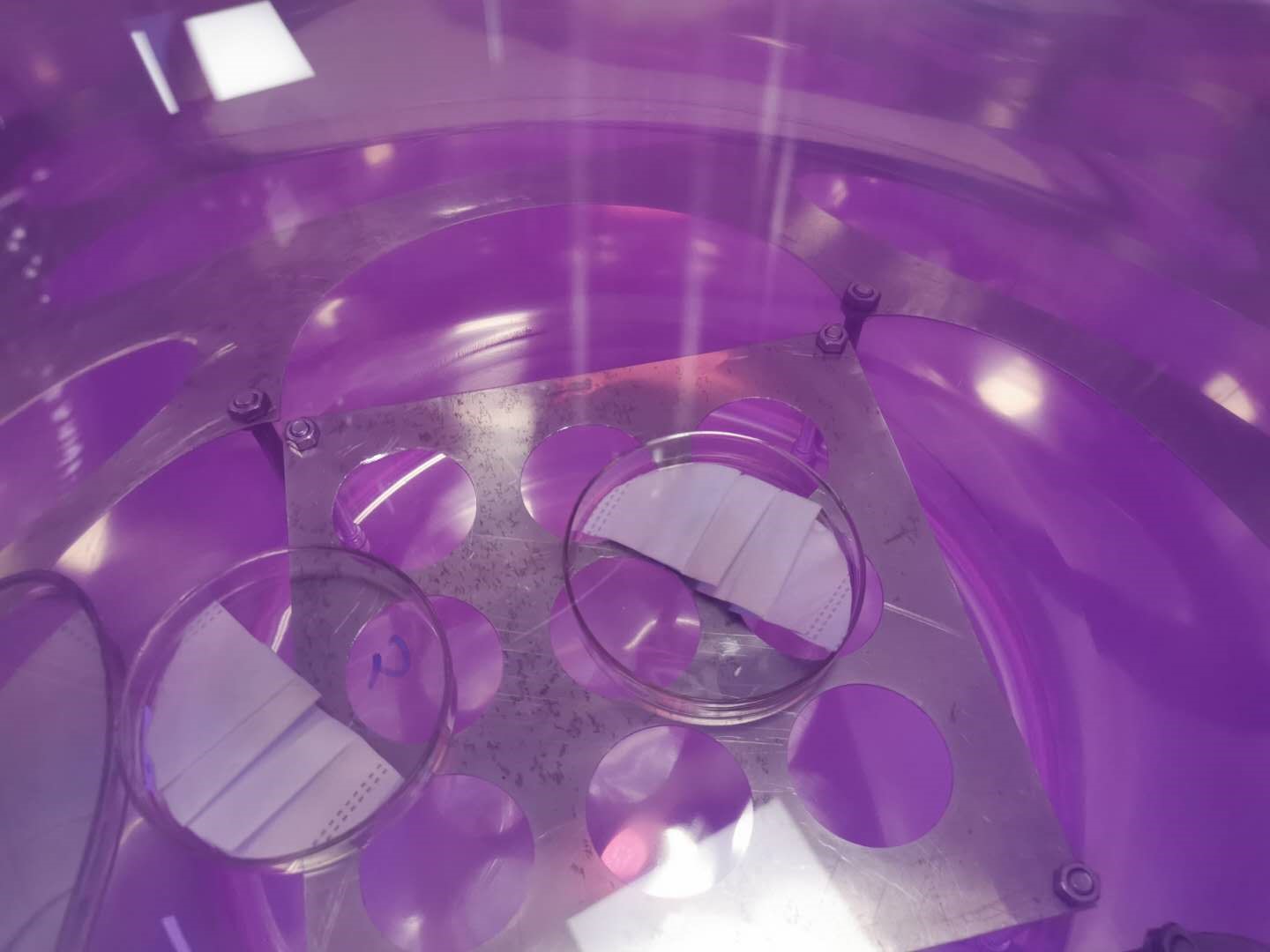

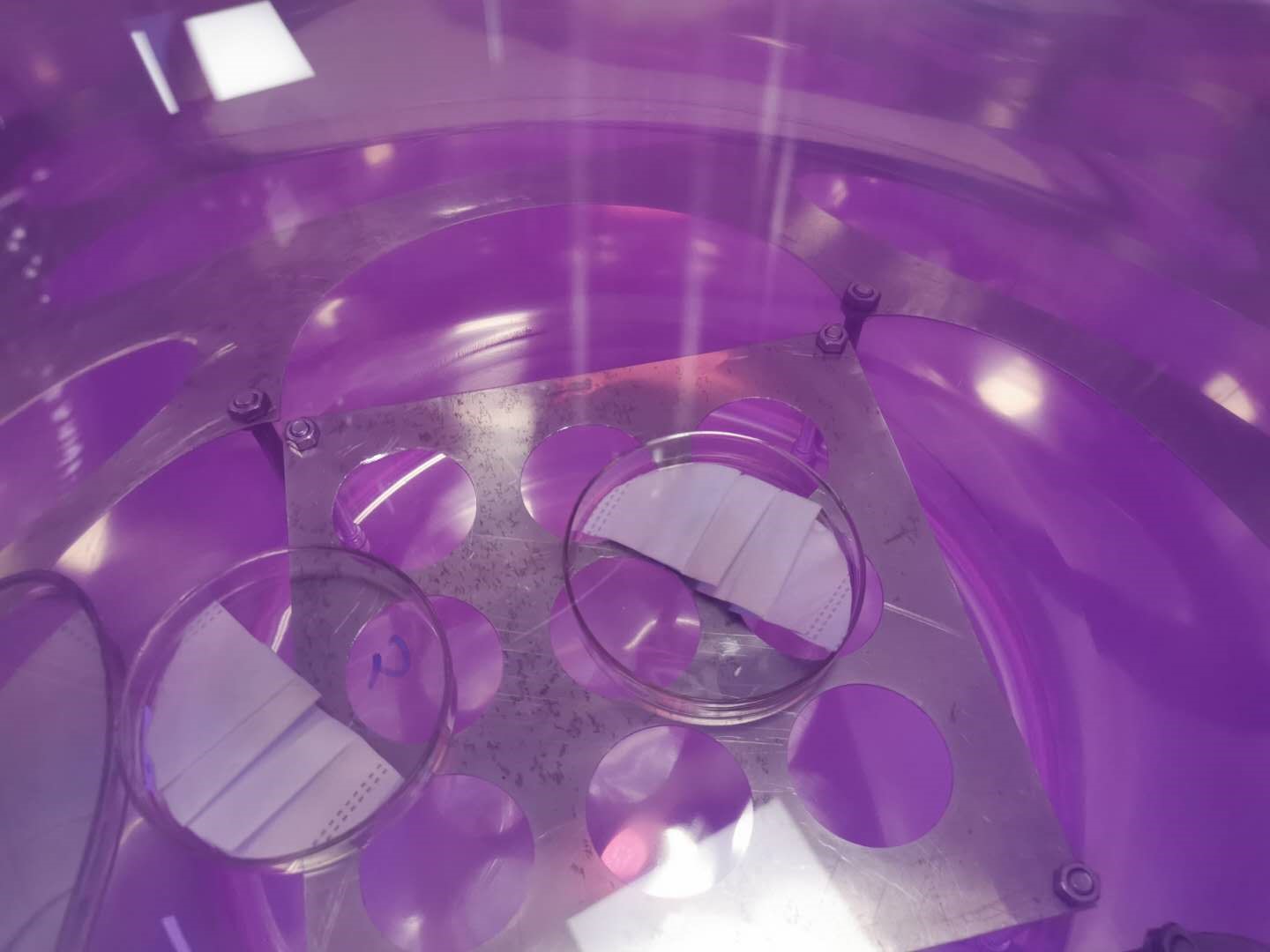

▲Plasma biological treatment machine

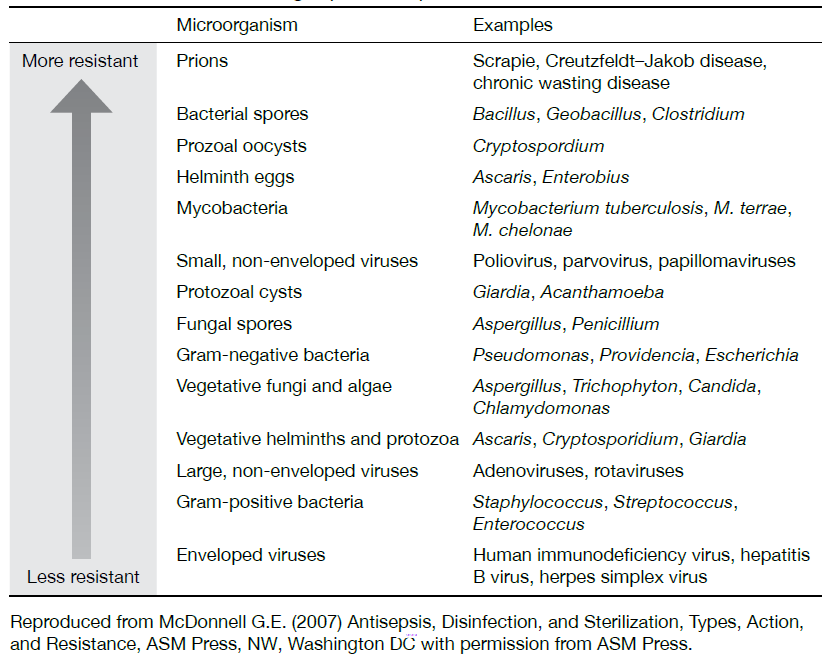

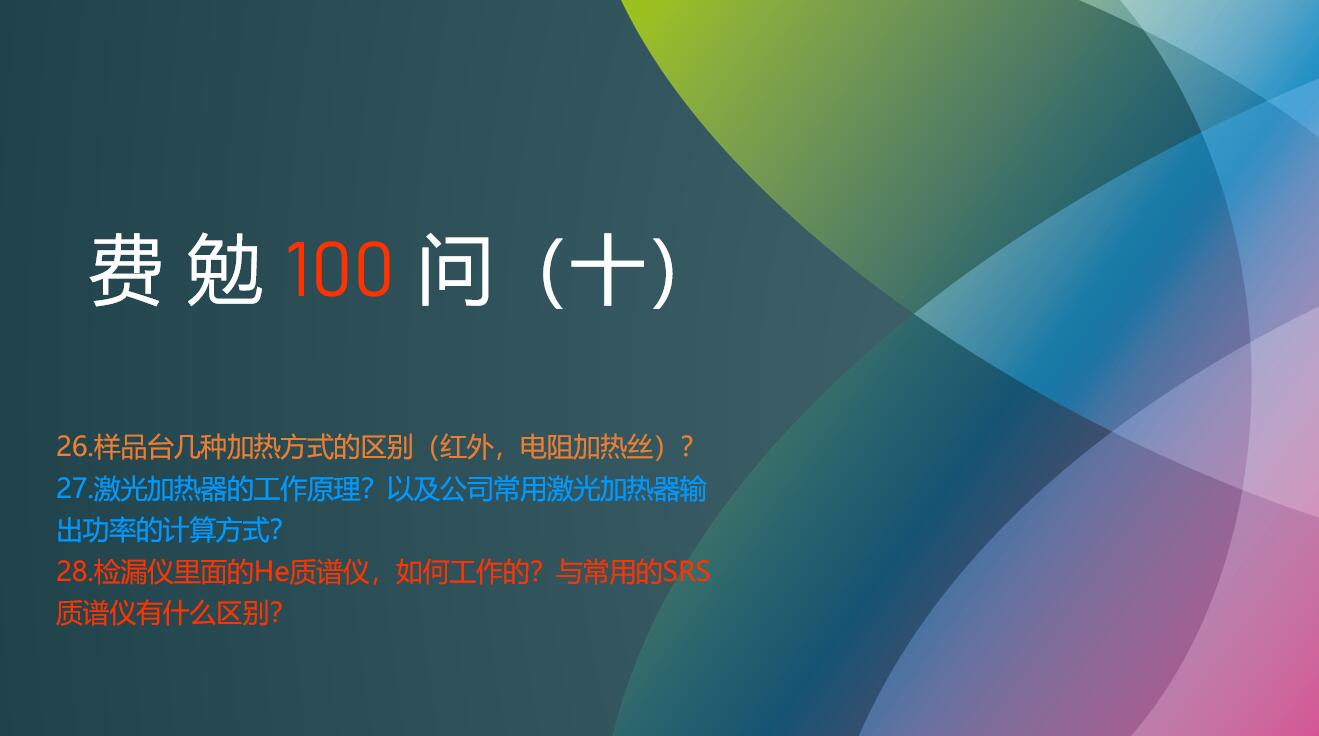

The advantages of plasma disinfection itself are low sterilization temperature, which can be applied to medical devices made of heat-sensitive materials; there are no toxic by-products and toxic residues, which is friendly and safe to the environment and operators; it has strong sterilization and disinfection capabilities, and has a strong effect on everything from common bacteria to the most difficult-to-kill spores, and is a broad-spectrum sterilizer.

▲Resistance of various bacteria, viruses, etc. to plasma gas

On this basis, Fermion Instrument's large-volume vacuum low-temperature plasma sterilization and purification equipment also has the following outstanding advantages. This device can use multiple remote plasma sources to form an array. Theoretically, it is not limited by volume and is suitable for batch processing. For example, a plasma treatment device with a storage capacity of 1 cubic meter has been successfully manufactured using this principle. If it is used for standard mask sterilization, it can process 10,000 masks at a time without any residue. The treated masks can be put into use immediately. We are currently discussing the specific operation process and feasibility with relevant manufacturers.

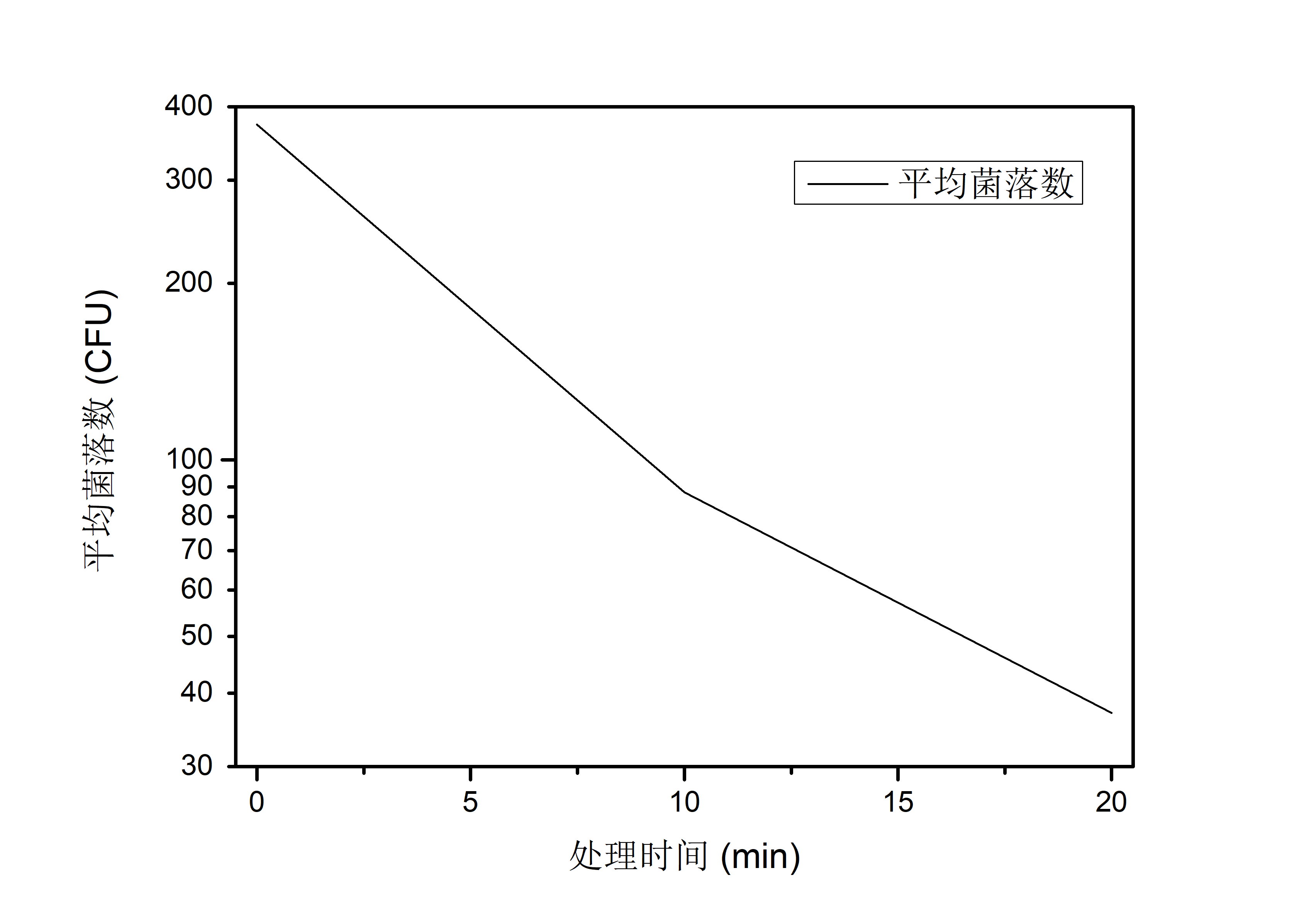

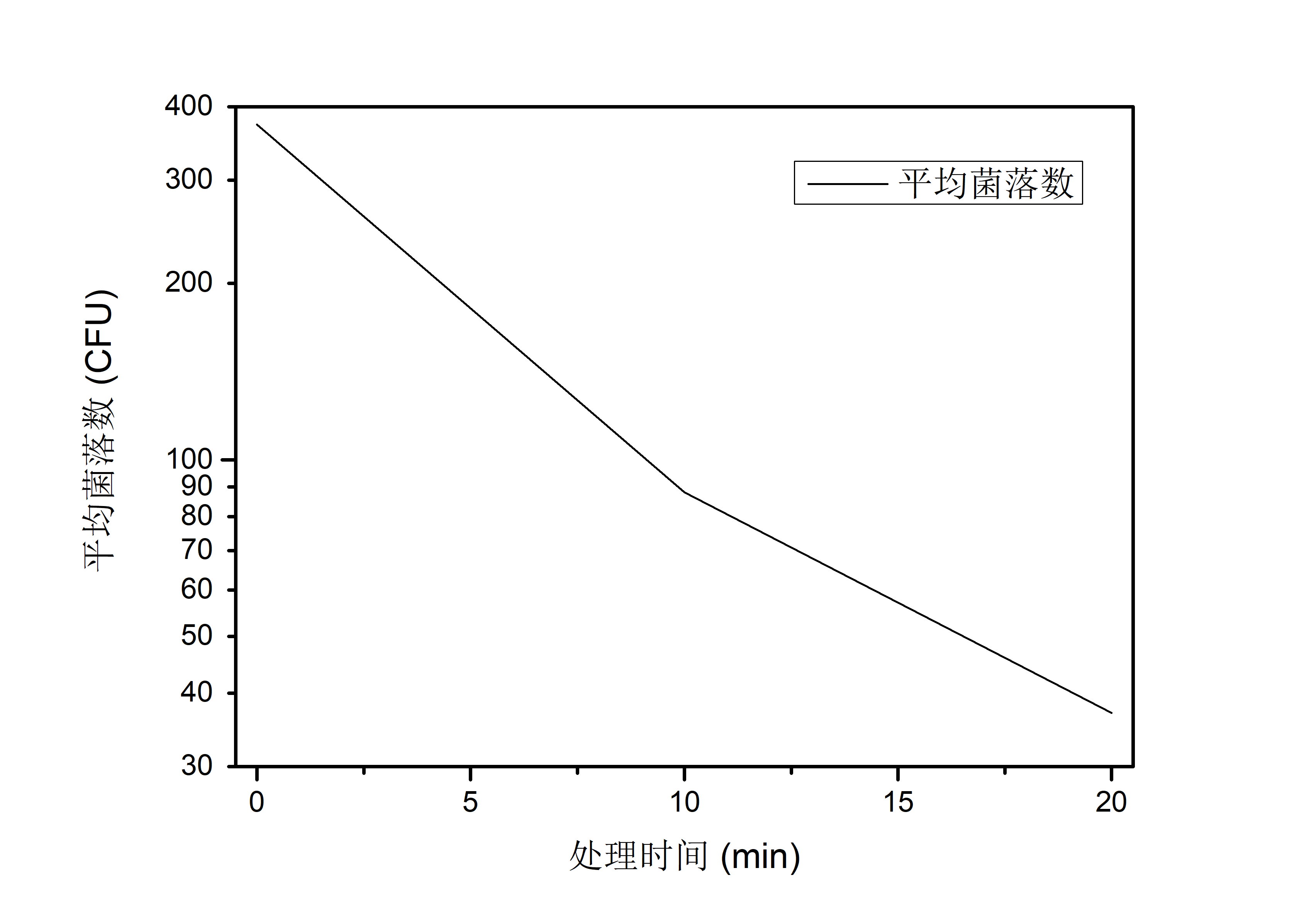

The sterilization speed is fast. According to relevant national standards, the change in the number of colonies after using plasma to treat Staphylococcus aureus can be observed. It can be seen that the average number of colonies has dropped rapidly by an order of magnitude;

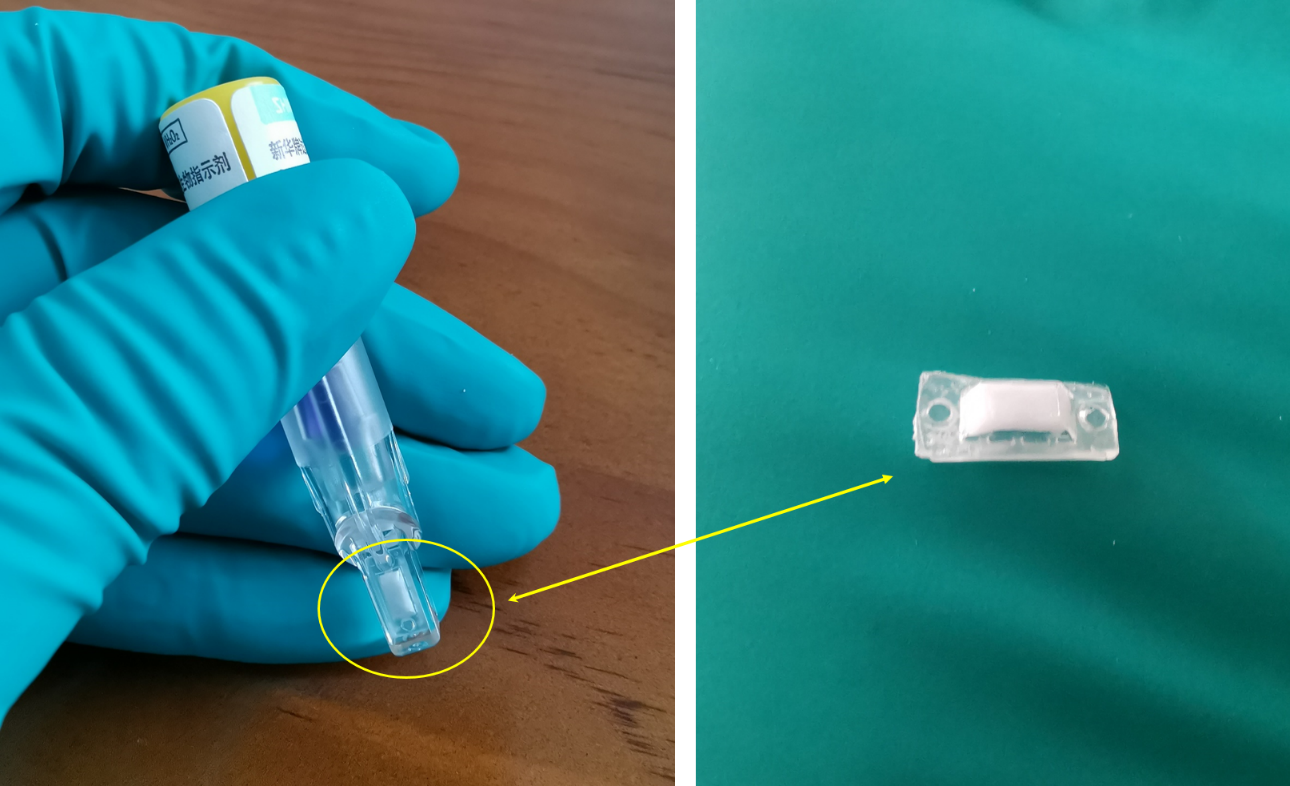

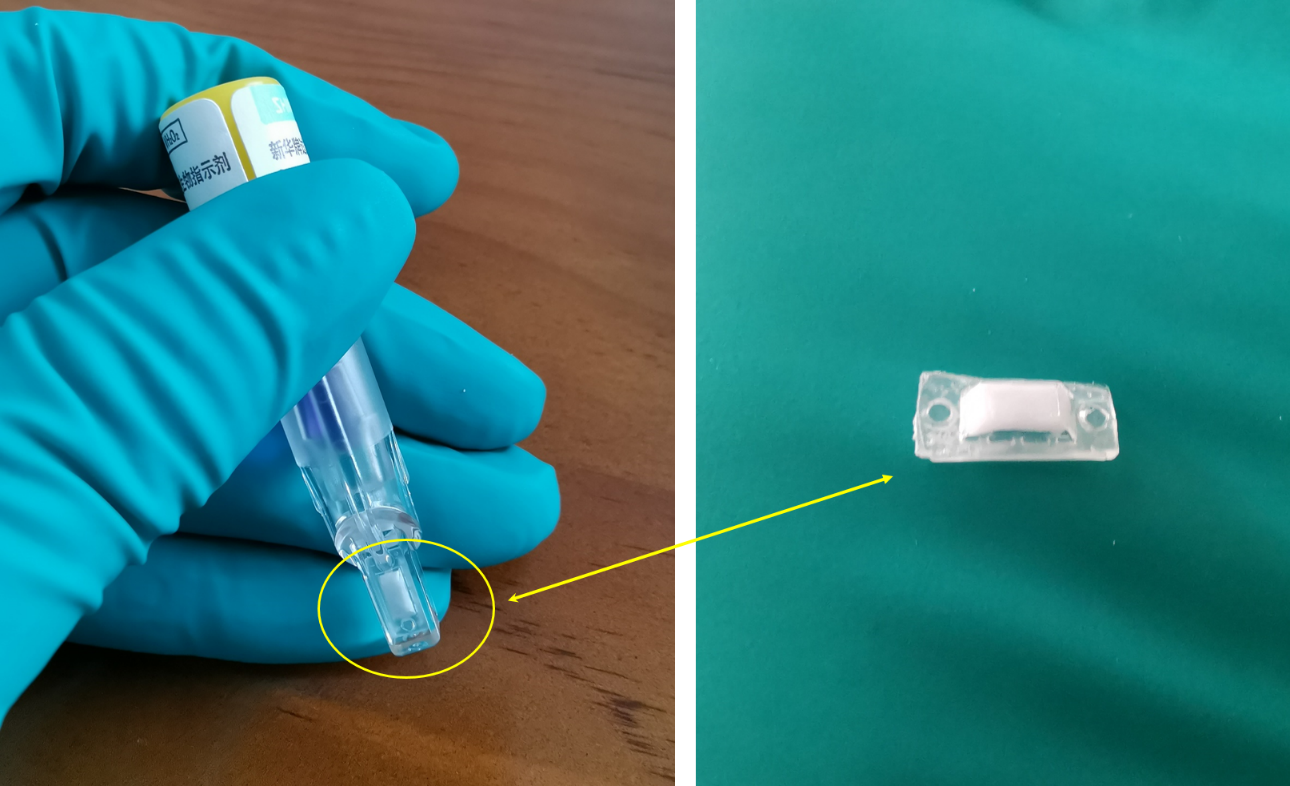

We also used Bacillus stearothermophilus spores for disinfection tests. Bacillus stearothermophilus spores are recognized as one of the most difficult species to kill in the field of plasma sterilization, and are harmless to the human body. They are also used as indicators of plasma sterilization effects. A single Bacillus stearothermophilus spore piece contains about 106 Bacillus stearothermophilus, while the number of bacteria on the surface of actual objects is usually within 102. Therefore, if all the spores in the indicator can be killed, it can be proved that the sterilization and purification technology has the ability to sterilize excessively.

▲Thermobacterium stearothermophilum spore biological indicator

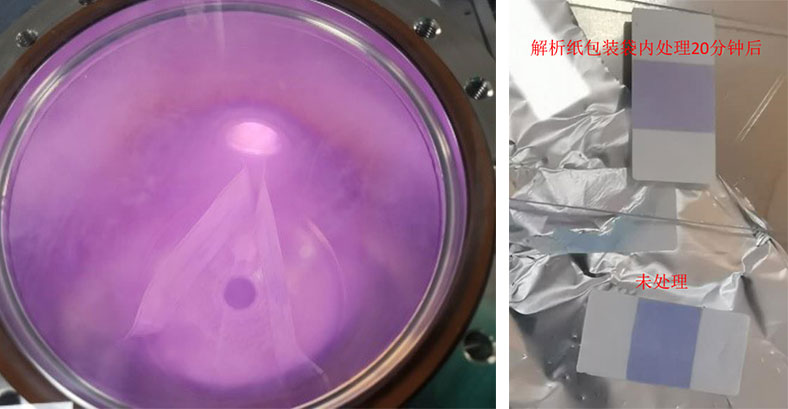

Under appropriate power and air pressure conditions, this plasma sterilization and purification technology can kill all excessive (106 level) thermobacterium stearothermophilum spores within 2 to 3 hours, which is sufficient to cope with actual scenarios. Through plasma active particle diffusion disinfection, it is not limited by the structure of medical devices, and can also achieve dead-angle sterilization of medical devices; the test in the figure below shows that this remote low-temperature plasma technology can make the plasma strength test paper change color quickly, indicating that the active particles produced by this technology can be diffused to a long distance, and the intensity is still sufficient to achieve the effect.

▲Plasma strength test

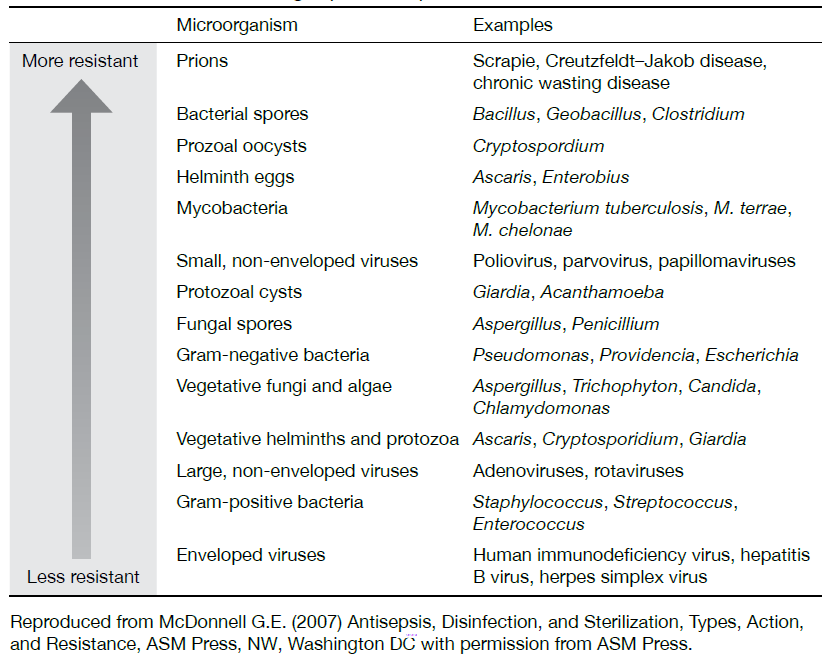

If the mask is sealed after disinfection, it may be contaminated again. Therefore, sealing first and then disinfecting is an effective solution. Usually, analytical paper is used to ensure the entry of gas molecules to avoid bacteria and viruses. In order to achieve packaging and disinfection, it is also necessary to ensure that the active particles in the plasma can pass through the analytical paper. Experiments have shown that the active particles produced by this technology can pass through the analytical paper, so that the test paper packaged in the analytical paper bag changes from blue to pink, thereby ensuring that the mask in the analytical paper package is effectively disinfected.

▲Plasma analysis paper permeability test

In addition, the equipment can use different gas sources as plasma working gases, such as air, oxygen, nitrogen, inert gas, etc., to achieve targeted sterilization and disinfection effects on different objects. The company is cooperating with relevant testing agencies to carry out systematic vacuum plasma sterilization and disinfection tests, as well as the development of plasma process technology for sterilization and purification of specific products. The relevant technology is expected to be further used in the material modification, hydrophilicity, hydrophobicity, antibacterial of mass living items such as textiles, as well as the degradation of pesticide residues in food and the decomposition of toxins (such as aflatoxin).

Label:

Your current location: Home > Technical Support > Popular Science Column > Application of ...

Your current location: Home > Technical Support > Popular Science Column > Application of ...