Your current location: Home > News > Delivery Case > Ultra-high vacu...

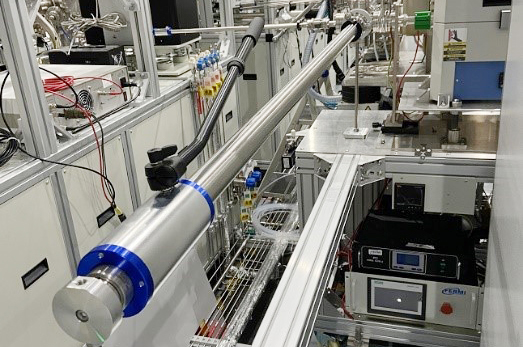

Your current location: Home > News > Delivery Case > Ultra-high vacu... In May 2020, the ultra-high vacuum PECVD system designed and built by Fermion Instruments was installed in Suzhou Institute of Nanotechnology and handed over to users.

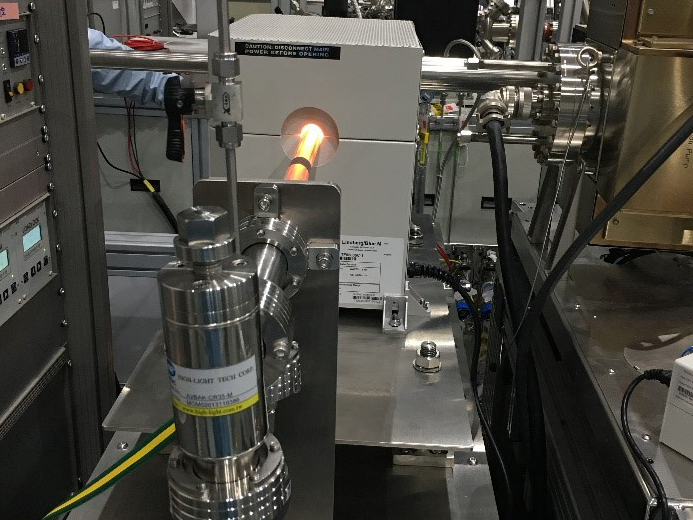

Traditional CVD systems have achieved good results in the field of material growth, especially the growth of two-dimensional materials such as graphene. CVD has advantages that other methods cannot match. Traditional CVD systems are usually based on tube furnace design, which fully utilizes the advantages of tube furnaces, such as corrosion resistance, easy cleaning, long constant temperature zone, and simple temperature control. However, conventional CVD systems are all single-unit equipment, and the grown materials need to be transferred through air to achieve further material modification or characterization. Many uncertain factors are introduced in the process, and oxidation and pollution in the air directly interfere with the intrinsic properties of the materials.

This ultra-high vacuum system completed by Fermion Instrument seamlessly connects CVD and ultra-high vacuum systems. It can not only complete CVD and even PECVD growth in a quartz tube furnace, but also directly send the produced crystal samples to STM and other analytical devices for measurement, greatly improving the sample quality and effectively improving scientific research capabilities.