Your current location: Home > Products > Industrial passivation > System equipment > Ultra-high vacuum cleavage coating system > Ultra-high vacu...

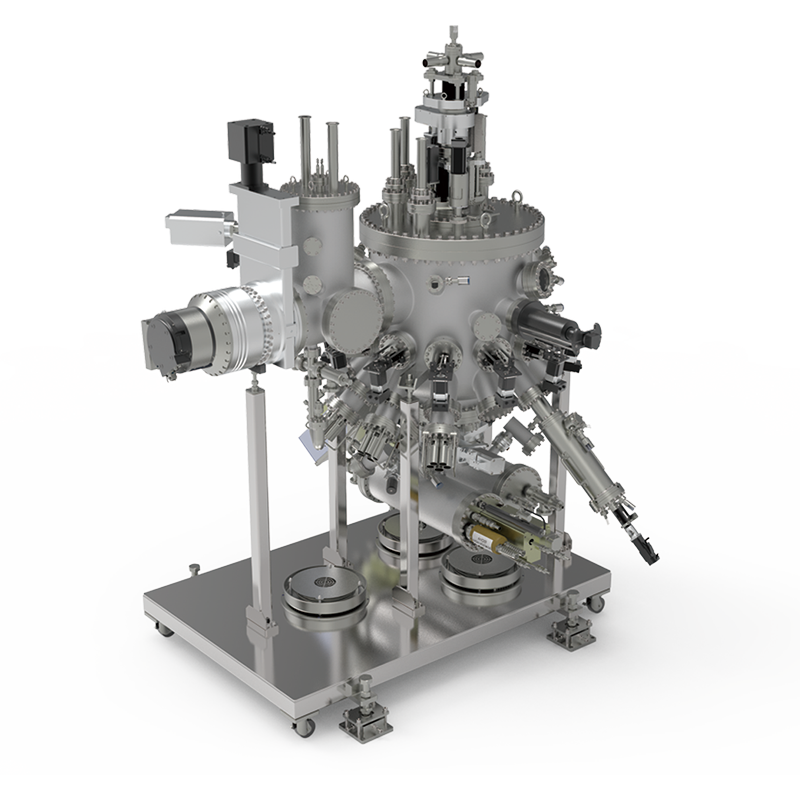

Your current location: Home > Products > Industrial passivation > System equipment > Ultra-high vacuum cleavage coating system > Ultra-high vacu... The vacuum cleavage coating system can realize ultra-high vacuum in-situ cleavage (Cleaving), passivation (Passivation) and optical coating (Optical Coating) of high-power laser bars. In-situ cleavage of laser diode bars in an ultra-high vacuum environment can obtain defect-free and pollution-free single crystal cleavage surfaces. The cleaved bars are transferred to the coating chamber through a circular transfer chamber (Cluster Tool) for passivation film or optical film evaporation. The entire process is carried out in an ultra-high vacuum environment better than 2*E-10 torr to achieve high-quality device production.

The fully automated robotic arm assembly is installed in the circular transfer chamber, with 360° rotation and telescopic functions, which can complete the automatic grasping and placement of the tray in each operating chamber. The robotic arm is equipped with a laser sensor and a visual positioning system to detect the real-time status of the robotic arm's movement in the system and can perform zero-point position correction.

The ultra-high vacuum cleavage system can realize manual or batch automated cleavage and stacking of bars, improving production efficiency.

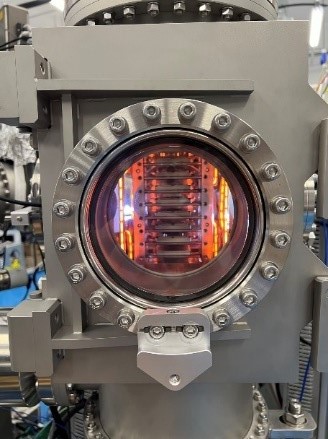

The coating chamber is designed based on the Fe-Mian standard MBE system. According to the requirements of the passivation layer evaporation process, various types of evaporation sources can be configured, including electron beam source (E-beam), thermal evaporation source (K-cell), plasma source (Plasma) and cracker source (Cracker). By using BFM, QCM, RGA, RHEED, etc., real-time in-situ characterization of the film layer can be performed. The chamber is equipped with a multi-dimensional motion sample parking table, which can cooperate with the required movement during sample transfer and coating. Each motion axis is equipped with a photoelectric signal detection system to ensure motion repeatability and safety. The coating process can be fully automatically controlled, including the three functions of growth process recipe writing, automatic growth control and uninterrupted data recording. All kinds of temperature and motion controls can be easily controlled on the PC side, and data curves can be read conveniently.

| Quickly enter and exit the sample chamber | |

| ● Can load 10 layers of sample trays, single tray with multiple stations; ● Infrared Bake-out bulb allows for rapid sample degassing; ● Remote plasma cleaning module, Cleaning of structural parts such as sample trays and sample racks can effectively improve the cleanliness and vacuum degree of the chamber; ● Independent operation of the sample inlet and sample outlet chambers improves production efficiency; |

| Circular transfer chamber | |

| ● Multiple flange ports on the side can be connected to multiple subsystems, and The subsystems operate independently and do not affect each other; ● The robotic arm has 360° rotation and telescopic functions; ● Cooperate with sensors and other control feedback to realize fully automatic sample transmission; Vacuum cleavage chamber ● Realize bar cleavage and stacking; ● Multiple samples can be processed in batches at one time; |

| Passivation coating chamber | |

| ● Multiple bottom flange ports, compatible with hot furnace source, electron beam evaporation source, RF plasma source, cracking source, etc.; ● Substrate heater temperature 650±0.5℃; ● Real-time beam monitoring, QCM crystal oscillator or BFM beam gauge; ● Real-time film layer monitoring RHEED; ● Multi-axis sample parking platform to achieve sample in-situ flipping or configure independent flipping chamber; ● Automatic growth system, uninterrupted data recording; |

After receiving the information, our sales personnel/product engineers will contact you

After receiving the information, our sales personnel/product engineers will contact you

Some products can be customized according to your needs

Some products can be customized according to your needs

Your information will be kept confidential throughout the entire process

Your information will be kept confidential throughout the entire process