Your current location: Home > Vacuum Technolo...

Your current location: Home > Vacuum Technolo... Ultra-high vacuum (UHV) refers to a vacuum state with a pressure lower than 1×10-8mbar. In this environment, the number of gas molecules is very small, the mean free path is about tens of kilometers, and they are in a molecular flow state. Almost all molecular interactions occur on the surfaces of the cavity. The typical atomic density of a solid surface is about 1015cm-2. Assuming that the molecules that collide with the surface are completely adsorbed, it only takes a few seconds to form a molecular monolayer under a vacuum pressure of 10-6mbar, while under a vacuum of 10-10mbar or 10-11mbar, the time to form a monolayer is several hours to dozens of hours. Therefore, clean material surfaces must be obtained and maintained in an ultra-high vacuum environment.

The application of UHV technology covers a wide range of fields, including materials science, surface science, semiconductor industry and optical research. In an ultra-high vacuum environment, researchers can more accurately study the properties of materials, explore surface chemical reactions and microstructures, and apply them to cutting-edge fields such as manufacturing high-performance electronic devices.

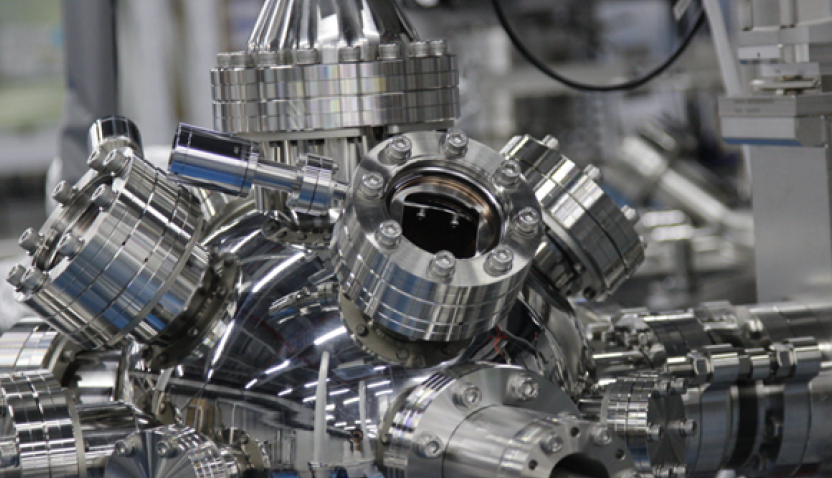

Ultra-high vacuum technology mainly involves the acquisition, measurement and maintenance of ultra-high vacuum, as well as movement under UHV conditions. Fermion Instruments has successfully mastered a series of precise and complex technologies involved in ultra-high vacuum conditions, including efficient vacuum pump systems, selection and processing of special materials, precise vacuum chamber design, and accurate vacuum measurement and control systems. The combined use of these technologies enables the ultra-high vacuum environment to not only provide extremely low gas molecule interference, but also stably maintain this high vacuum state. We have successfully independently developed a number of core components of vacuum systems and obtained 28 authorized patents in the vacuum field.

Our self-produced vacuum components can not only meet the multi-dimensional linear and rotational motion of users in ultra-high vacuum environments, but also achieve stable and accurate sample transfer in vacuum systems.

All vacuum components are made of ultra-high vacuum compatible materials and can operate stably in the working pressure range of 10-11mbar to 1bar.

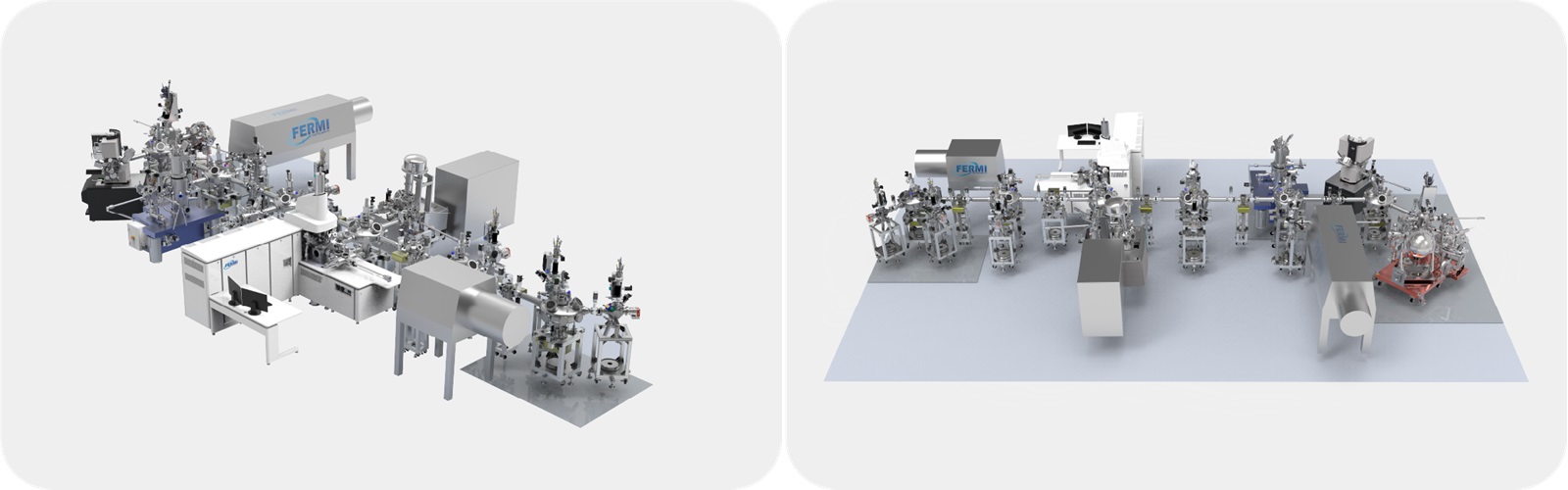

The ultra-high vacuum linear interconnection system can integrate a variety of functional equipment such as material preparation, material processing, material characterization and measurement to achieve comprehensive physical property research throughout the material life cycle.

The linear interconnection system adopts a modular design with strong scalability, and the ultimate vacuum can reach 10-11mbar.

The circular sample transfer interconnection system is based on the modular design of the multi-channel circular sample transfer system, with a compact structure and efficient operation. It is suitable for both small laboratory-level interconnection construction and large-scale equipment platform construction.

The ultimate vacuum of the circular sample transfer interconnection system can reach 10-11mbar, and solid lubrication film technology is used, which is reliable and durable.