Your current location: Home > Products > Industrial MBE > System equipment > MBE800 Molecular Beam Epitaxy System > MBE-800 molecul...

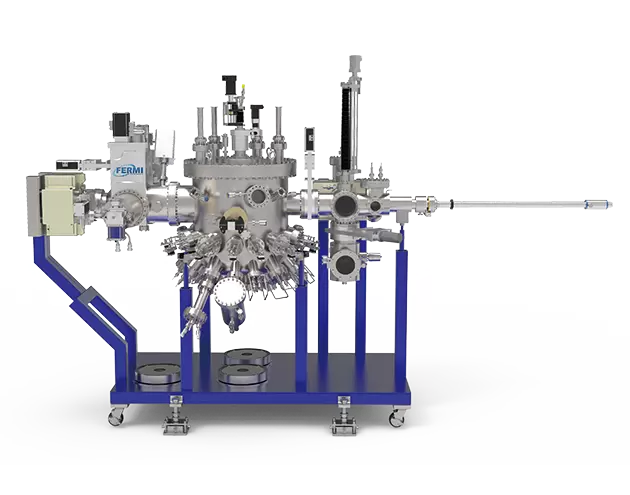

Your current location: Home > Products > Industrial MBE > System equipment > MBE800 Molecular Beam Epitaxy System > MBE-800 molecul... In order to achieve epitaxial growth of materials on 4-inch wafers, Fermion Instrument has launched the MBE-800 molecular beam epitaxy system. The standard version system adopts a dual temperature zone substrate heater and includes 12 evaporation source ports, which can achieve precise layer by layer growth of complex structured thin films. The customized version of MBE-800 also covers specific production needs, such as ultra-high vacuum ion assisted coating systems.

The MBE-800 system has high reliability, versatility, and compactness, and is compatible with epitaxial growth on substrates under 4 inches. This system can not only serve as an application development device, but also be suitable for quasi batch production applications.

| MBE-800 Manual sample transfer system | |

| MBE-800 Manual sample transfer system,By using a magnetic coupling transfer rod, 4-inch samples can be transferred. The robotic arm can travel up to 1200mm, meeting the requirements for substrate transfer between the growth chamber and the pre-processing chamber. At the same time, the robotic arm can provide a movement space of 25mm in the vertical direction, meeting the requirements for substrate retrieval and placement operations. This sample transfer system does not require the use of secondary motion tools, greatly simplifying the substrate transfer steps while reducing costs. |

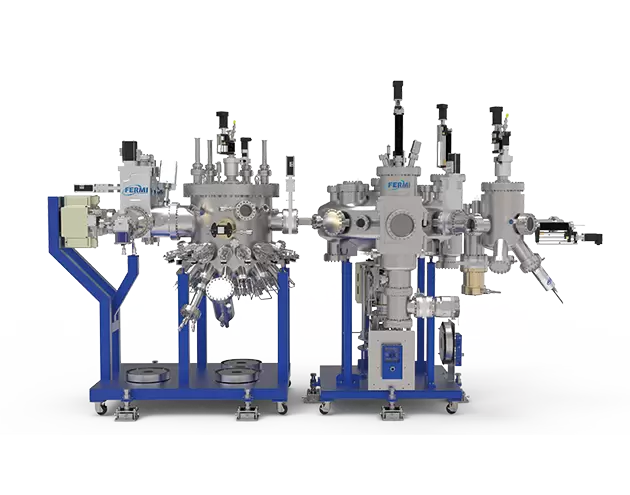

| MBE-800 Fully automatic sample transfer system | |

| MBE-800 Cluster Fully automatic sample transfer system,Integrating different chambers on a circular sample transfer chamber, coupled with a 360 ° continuously rotating robotic arm component, with a maximum stroke of 1350mm, can achieve vacuum transfer of substrates between different chambers. The robotic arm is driven to rotate by a high torque magnetic coupling driver, and precise positioning is achieved by a positioning substrate installed at the front end of the robotic arm. The robotic arm can provide 0-25mm free movement in the vertical direction through linear drive, achieving substrate picking and placing operations. |

According to customer requirements, Fermion Instrument provides different models of thermal evaporation sources, cracking sources, electron beam evaporation sources, and gas sources. The system can install RHEED, QCM, BFM, RGA, OFM, etc. to achieve in-situ monitoring of thin film growth. Fermion Instrument provides MBE operation software, including three major functions: growth process program writing, automatic growth control, and uninterrupted data recording. It can execute growth process program to control baffle movement, source furnace temperature, substrate temperature, substrate rotation speed and direction. The control software includes process requirements such as temperature curve, vacuum pressure curve, power output curve, and sample transfer between various systems to ensure the repeatability and safety of the growth process.

| Configuration | MBE-800 | |

| Growth chamber | Cavity Size | 650mm I.D. |

| Vacuum | <2×10-10mbar | |

| Liquid nitrogen cold screen | Standard configuration | |

| Extreme vacuum after passing liquid nitrogen through the cold screen | <5×10-11mbar | |

| Maximum temperature of substrate heater | 1000℃ | |

| Temperature stability of substrate heater | PID control,±0.5℃ | |

| Maximum size of substrate | 4inch | |

| Substrate rotation | 60RPM | |

| Steam source configuration | CF63×2/CF100×7 / CF125×3 | |

| Independent evaporation source shutter | motor drive | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Baking temperature | 200℃ | |

| Prepare Chamber | Vacuum | <2×10-10mbar |

| Water-cooled interlayer of the cavity | Optional | |

| Maximum temperature of pre-treatment heater | 450℃ | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Load lock | Vacuum | <1×10-8mbar |

| Water-cooled interlayer of the cavity | Optional | |

| Sample Parking Platform | 4-10 pieces | |

| Infrared baking lamp | Optional | |

| Full range gauge | 1×103~5×10-9mbar | |

| Cluster Chamber | Vacuum | <5×10-10mbar |

| Pressure during sample transmission | <1×10-9mbar | |

| Maximum manual sample transfer travel | 1200mm | |

| Automatic sample transfer maximum travel | 1350mm | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Storage Chamber | Sample Parking Platform | 10 (optional) |

| System control | Touch screen operation panel | Standard configuration |

| Programming of growth process | Standard configuration | |

| Automatic growth control | Standard configuration | |

| Continuous data recording | Standard configuration | |

| Alarm protection function | Standard configuration | |

| Interlocking function | Standard configuration | |

| Optional | CCD | Optional |

| Glove box | Optional | |

| Phosphorus recovery system | Optional | |

| Substrate infrared temperature measurement system | Optional | |

| Vacuum lighting system | Optional | |

| SMS | Optional |

After receiving the information, our sales personnel/product engineers will contact you

After receiving the information, our sales personnel/product engineers will contact you

Some products can be customized according to your needs

Some products can be customized according to your needs

Your information will be kept confidential throughout the entire process

Your information will be kept confidential throughout the entire process