Your current location: Home > Products > Industrial MBE > System equipment > MBE600 Molecular Beam Epitaxy System > MBE-600 molecul...

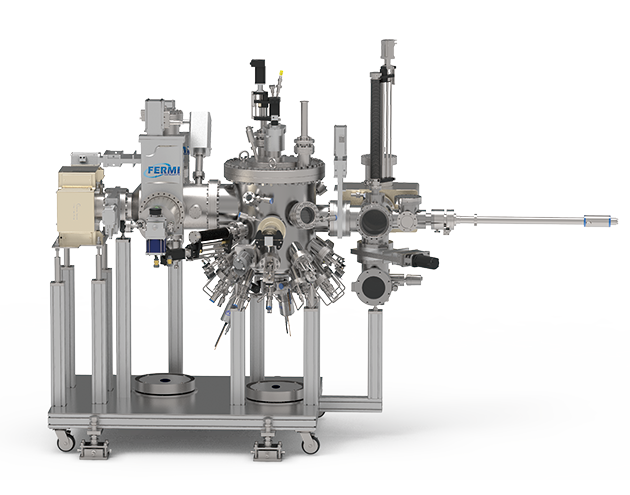

Your current location: Home > Products > Industrial MBE > System equipment > MBE600 Molecular Beam Epitaxy System > MBE-600 molecul... The MBE-600 system is highly suitable for III-V, II-VI material applications, as it can epitaxy on 1, 2, and 3-inch substrates. Its vertical chamber design and various advanced components enable precise layer by layer epitaxy.

The outstanding features of the MBE-600 system are its high reliability, versatility, and compactness, which make it particularly suitable for research and development applications as well as quasi mass production. The standard version of MBE-600 includes 10 source ports, with 7 flange sizes of 4.5 inches (DN63CF) and 3 flange sizes of 2.75 inches (DN35CF). The customized version of MBE-600 also covers specific production needs, such as ultra-high vacuum cleavage coating systems.

According to the requirements of all our customers, we provide different types of ordinary evaporation sources, cracked sources with valves, gas sources, and electron beam evaporation sources. By using BFM, QCM, RHEED, RGA, etc., in-situ characterization of the system can be obtained. Fermion's MBE software includes three major functions: programming for growth processes, automatic growth control, and uninterrupted data recording. The growth process program can be executed to control the movement of the baffle, source furnace temperature, substrate temperature, substrate rotation speed and direction. Ensure maximum operational repeatability and safety. The control software includes process requirements such as temperature curve, vacuum pressure curve, power output curve, and sample transfer between various systems.

| MBE-600 Manual sample transfer system | |

| Can perform 3-inch substrate transfer. Fermion Instrument transforms traditional substrate transfer methods into a fully functional device. This system not only provides horizontal linear motion for substrate transfer, but also offers up to 25 mm of vertical movement space for up and down movement to remove or place substrates. This system does not require the use of secondary motion tools, reducing costs and greatly simplifying substrate transfer technology. |

| MBE-600 Cluster Fully automatic sample transfer system | |

| The substrate can be easily transferred to various chambers without compromising the vacuum level of the MBE chamber. Cluster Tool is a mechanical arm component installed on the top or bottom of a UFO, which can rotate continuously 360 °, with the purpose of transferring substrates throughout the MBE system; Paired with a linear drive device, it achieves free movement in the vertical direction of 0-50mm, with the aim of placing and grasping substrates. The end of the robotic arm can be paired with a 3-inch substrate gripping head, with a maximum load capacity of 1kg. The robotic arm is driven by a high torque magnetic coupling driver to rotate to the desired vacuum chamber port, and the positioning substrate is installed on the front end of the robotic arm to detect the process of the robotic arm moving the substrate within the system module. |

| Configuration | MBE-600 | |

| Growth chamber | Cavity Size | 450mm I.D. |

| Vacuum | <2×10-10mbar | |

| Liquid nitrogen cold screen | Standard configuration | |

| Extreme vacuum after passing liquid nitrogen through the cold screen | <5×10-11mbar | |

| Maximum temperature of substrate heater | 1000℃ | |

| Temperature stability of substrate heater | ±0.5℃ | |

| Maximum size of substrate | 3inch | |

| Substrate rotation | 60RPM | |

| Steam source configuration | CF35×3/CF63×7 | |

| Independent evaporation source shutter | Motor drive | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Baking temperature | 200℃ | |

| Prepare Chamber | Vacuum | <2×10-10mbar |

| Maximum temperature of pre-treatment heater | 450℃ | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Load lock | Vacuum | <1×10-8mbar |

| Sample Parking Platform | At least 4+2 | |

| Infrared baking lamp | Optional | |

| Full range gauge | 1×103~5×10-9mbar | |

| Sample Chamber | Vacuum | <5×10-10mbar |

| Pressure during sample transmission | <1×10-9mbar | |

| Manual/Fully Automatic | Optional | |

| Ionic gauge | 1×10-3~2×10-11mbar | |

| Sample Parking Platform | At least 4+2 | |

| System control | Touch screen operation panel | Standard configuration |

| Programming of growth process | Standard configuration | |

| Automatic growth control | Standard configuration | |

| Continuous data recording | Standard configuration | |

| Alarm protection function | Standard configuration | |

| Interlocking function | Standard configuration | |

| Optional | CCD | Optional |

| Glove box | Optional | |

| Phosphorus recovery system | Optional | |

| Substrate infrared temperature measurement system | Optional | |

| Vacuum lighting system | Optional | |

| SMS | Optional |

After receiving the information, our sales personnel/product engineers will contact you

After receiving the information, our sales personnel/product engineers will contact you

Some products can be customized according to your needs

Some products can be customized according to your needs

Your information will be kept confidential throughout the entire process

Your information will be kept confidential throughout the entire process