Your current location: Home > Products > R&D Instruments > Sample processing > Atmosphere treatment > High temperature and high pressure reaction pool > High temperatur...

Your current location: Home > Products > R&D Instruments > Sample processing > Atmosphere treatment > High temperature and high pressure reaction pool > High temperatur... The HPGC high-temperature and high-pressure gas reaction cell is an in-situ sample heating device under atmospheric conditions, which can be connected to various analytical systems that require in-situ preparation functions. The maximum heating temperature of the reaction cell is 1200 K, and the maximum pressure tolerance of the internal atmosphere is 10 bar. It has the characteristics of small size, strong pressure bearing, convenient operation and a wide range of applicable gases.

The device is mainly composed of several parts such as the reaction chamber, the sample transfer system and the gas mixing system. The outer wall of the reaction chamber is made of stainless steel with strong pressure bearing capacity; the inner sleeve is a thick-walled quartz tube, which uses the stability of the quartz material to ensure that the gas in the reaction chamber does not react with the quartz, protects the cavity itself from being damaged, increases the types of available gases, and improves the reliability of the experimental results; the closed volume of the entire reaction chamber is very small, about 100 ml, which greatly enhances the safety of the equipment. The heating part uses a heating wire and a thermocouple (K type) to achieve automatic temperature control and heating functions, and the heating wire works under vacuum conditions, which can extend its service life; in addition, the good insulation system design significantly reduces the temperature of the sealing part, so the sealing part uses a reusable high-fluorine rubber ring to replace the traditional copper gasket, which greatly reduces the cost. In addition, the use of a water-cooling jacket circulation device to cool the outer wall of the reaction chamber can effectively reduce the surface temperature of the reaction chamber, enhance the pressure-bearing capacity of the stainless steel outer wall, and protect the personal safety of operators.

| Configuration | HPGC-300 | |

| Reaction Chamber | Heating Type | Radiant Heating, Corrosion-Resistant Heating Wire Supported by Ceramic Plates |

| Thermocouple Type | Type K | |

| Operating Temperature | 300-1200 K | |

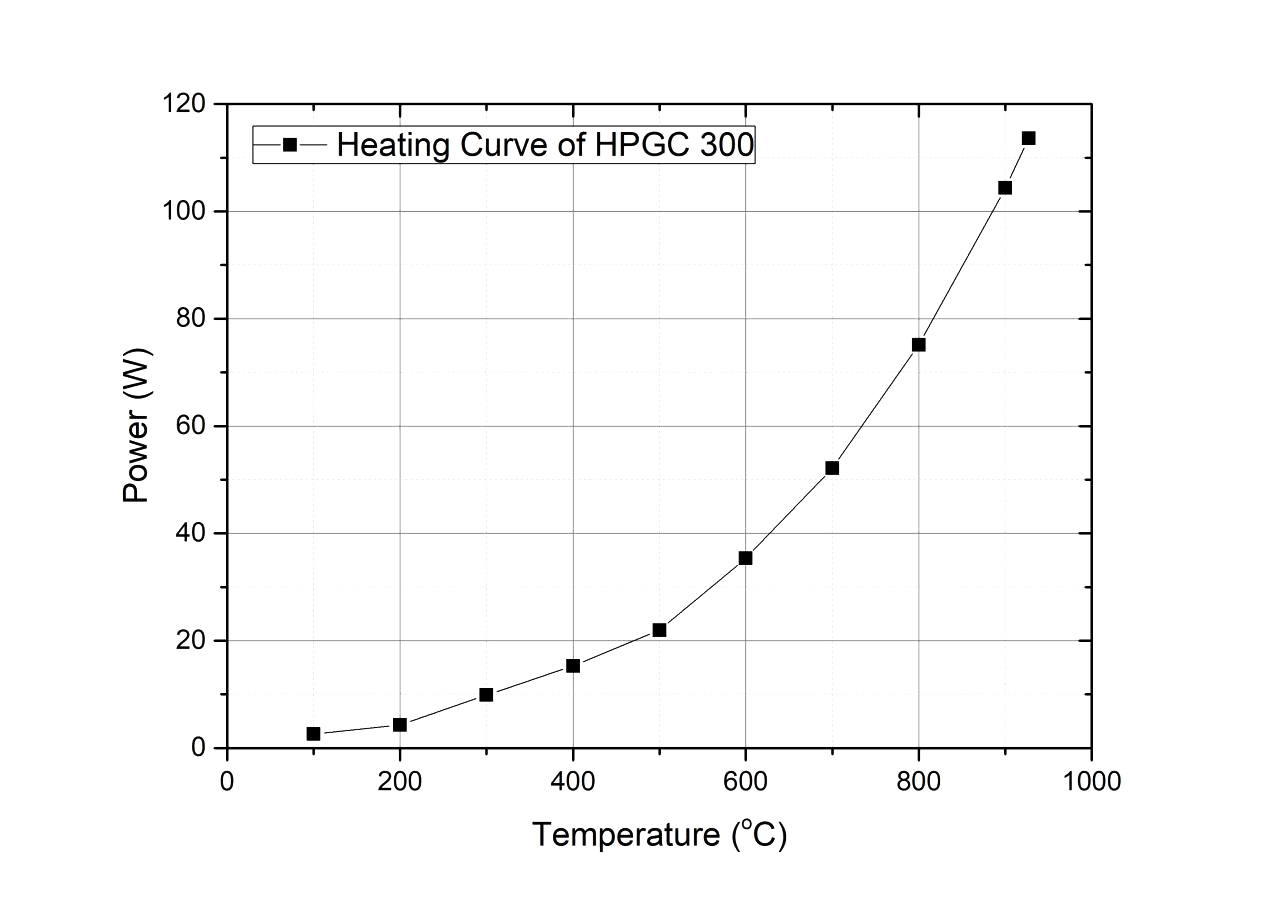

| Maximum heating power | 150 W | |

| Temperature stability | ≤0.1℃, depends on PID thermostat | |

| Water cooling | Internal water cooling | |

| Chamber volume | 100ml | |

| Maximum reaction gas pressure | 10 bar | |

| Applicable gas types | Ar, N2, O2, etc | |

| Unsuitable gas types | F2, Cl2, Br2 and other halogens | |

| Vacuum | Foreline pump, background 5E-2mbar / molecular pump group, background 5E-6mbar | Optional |

| Sample transfer | Left/right side | Optional |

| Sample transfer distance | 120mm | |

| Adapter flange | CF40/CF63/CF100 | Optional |

| Mixing chamber | Maximum working pressure | 10Bar |

| Number of gas lines | Including four mixing gas lines and one purge gas line | |

| Chamber material | SS316 | |

| Chamber volume | 270ml | |

| Movable device | Roller bracket | |

| Outlet connection | 1.5m high pressure hose, 1/4" stainless steel straight pipe interface | |

| Overpressure protection | 10Bar | |

| Exhaust treatment panel | Exhaust pressure control 1~16Bar | |

| Analog mass flow meter/digital mass flow meter/none | Optional |

After receiving the information, our sales personnel/product engineers will contact you

After receiving the information, our sales personnel/product engineers will contact you

Some products can be customized according to your needs

Some products can be customized according to your needs

Your information will be kept confidential throughout the entire process

Your information will be kept confidential throughout the entire process